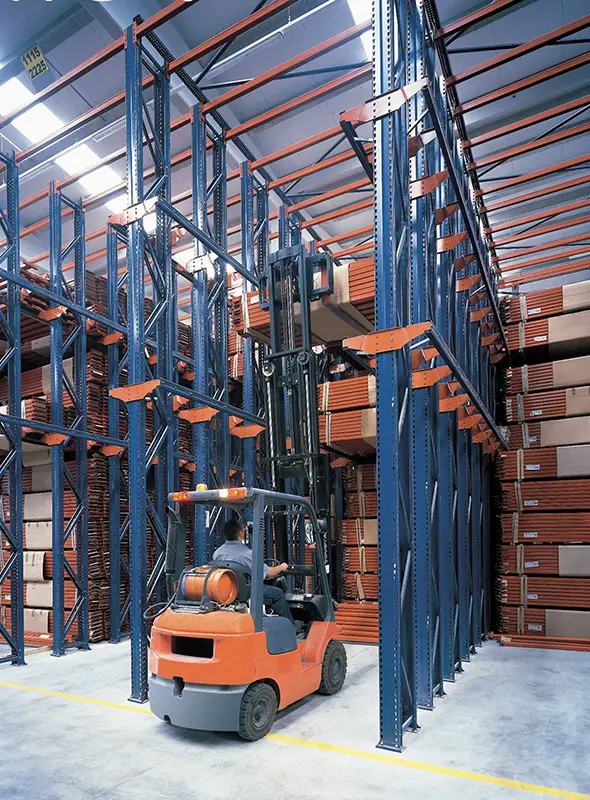

At FCSI, we specialise in providing high-quality “Drive-in Pallet rack systems in Dubai”. These systems are designed to optimize space for businesses that require maximum storage density, making them a perfect solution for warehouses with limited space, fragile products, or cold storage requirements. Our drive-through Pallet racking systems are a cost-effective way to manage high volumes of homogeneous products without compromising durability or efficiency. They slide backward on rails, creating more space without removing pallets, while forklifts load and unload from one side.

Drive-In Pallet Rack Systems Manufacturer & Supplier in Dubai

FCSI Tech is a leading “drive-in pallet rack dealer and supplier in Dubai”. It is known for manufacturing cutting-edge racking solutions that enhance storage capacity and streamline operations. Whether you are dealing with fragile products, materials that need cold storage, or sheet metal storage, our Drive-in pallet racks are engineered to meet diverse business needs.

Advantages of FCSI’s Drive-in Pallet Rack Systems

FCSI’s Drive-in Pallet Racking Systems provide an efficient solution for businesses seeking high-density storage and optimised warehouse space. Here are the key benefits:

- Maximized Storage Capacity: Our systems maximize floor and vertical space, allowing up to 80% space utilization by storing multiple pallets deep within each bay.

- Space Optimization: Perfect for cold storage and standard warehouses, our systems maximize vertical and floor space, allowing more products to be stored without expanding your warehouse size.

- High Storage Density: Ideal for storing large quantities of similar products, our racking systems are compatible with both First In Last Out (FILO) and First In First Out (FIFO) configurations.

- Improved Inventory Control: Our design supports efficient logistics management and better inventory control, ensuring smooth operations.

- Cost-Effective: With low assembly and maintenance costs, our systems provide an affordable storage solution without compromising quality.

- Durable & Modular: Made from high-quality materials, the modular design ensures long-lasting durability and easy reconfiguration to adapt to business changes.

- Safety & Reliability: Built to meet industrial safety standards, our systems ensure secure storage for heavy and fragile products, with a reputation for quality and customer satisfaction.

In summary, FCSI’s Drive through Pallet Racking Systems are ideal for maximizing storage space, reducing costs, and ensuring efficient inventory management, making them a reliable solution for any industry.

Features of Our Drive-in Pallet Racking Systems

- Column and row end protectors for durability and damage prevention

- Heavy-duty struts, boxed and recessed columns for strength and stability

- Floor channel and angle stops for pallet alignment and security

- Maximizes space with high-density storage for floor and vertical use

- Cost-effective for cold and chilled storage; no special handling equipment required

- Ideal for limited stock rotation and seasonal goods with FILO accessibility

- Smooth pallet rails and brightly colored pallets for easy, snag-free load positioning

- Protects fragile loads, reducing damage, perfect for bulk and batch dispatch storage

- Suitable for low stock rotation, cold, and bulk storage applications

Types of Drive-in Racking Systems

We offer two main types of Drive-in racking systems designed to suit different storage needs:

- Single Entry Drive-in Racking: This type allows forklift access from one side, making it ideal for businesses that operate on a First-in-Last-out (FILO) basis. It is also perfect for high-density storage, where products are retrieved in the reverse order of how they were stored.

- Double Entry Drive-in Racking: This system provides forklift access from both sides, allowing for a more flexible Drive-in pallet rack system in Dubai. This is especially beneficial for First In First Out (FIFO) operations and businesses needing quick access to both ends of the pallet rack.

Drive-In Pallet Racking for LIFO or FIFO Inventory

Drive-in pallet racking is ideal for LIFO (Last In, First Out) and FIFO (First In, First Out) inventory systems.

For LIFO, commonly used in this setup, pallets are loaded and retrieved from the same side, maximizing storage density for non-perishable or low-rotation goods.

For FIFO, a drive-through rack system allows loading from one side and retrieval from the opposite, ensuring first-loaded products are the first to be accessed. This is useful for time-sensitive products like food and beverages.

Whether using LIFO or FIFO, drive-in pallet racking offers a flexible, high-density storage solution to optimize warehouse space.

Along with commercial projects such as office fit-out and racking & shelving installations, our team also handles villa renovation work in Dubai, including interior upgrades and structural changes.

Drive-in racking allows forklifts to enter the storage lanes from one side, placing and retrieving pallets stacked multiple levels deep. The pallets rest on rails and can be slid backward to create space. This system operates on a first-in, last-out (FILO) basis; the pallet loaded by the first-in and last-outlet is the first to be retrieved. It is ideal for high-density storage where full access to every pallet is not required.

Drive-in pallet racks are best suited for storing large quantities of similar items. They are commonly used for products that do not need immediate access, such as bulk materials, non-perishable goods, and items stored in cold environments.

These can be used in Cold storage facilities, Warehouses, Manufacturing units, Retail stockrooms, the Food and beverage industry, Agriculture, Automotive, Chemical, barrel storage, and the Pharmaceutical industry, among others.

Drive-in pallet racks are constructed with steel and welded design, which allows them to handle heavy loads without bending. The frame of the racks ensures durability and is built for even weight distribution, which is ideal for heavy-duty warehouse use.